What is fiber?

Fiber production creates clothing and goods for warmth and protection, or beauty in art. Fiber literally and figuratively weaves together ancient traditions, modern manufacturing, and technology. In Maine, fiber is common farm product. Fiber may be non-agricultural too. For example, synthetic materials compose a variety of textiles made in the U.S. and across the world.

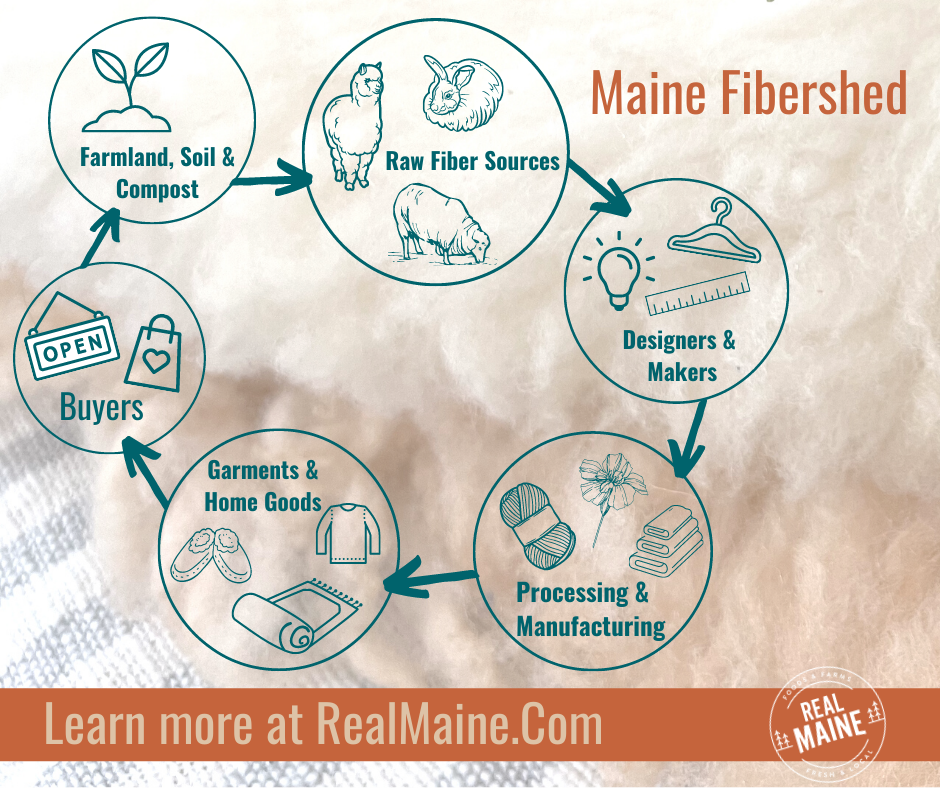

What is a “fibershed”?

A fibershed includes fiber production, use, and recycling in a geographic area. A farm, for example, may involve many parts of the fibershed. On the other hand, a different business may focus on a single role, such as processing, or making a finished product. Like most systems or cycles, the moving parts of a fibershed are not always linear.

Raw Materials

Raw materials are a key part of the fibershed. For instance, shearing or trimming fleece and hair from farm animals produces raw materials. Harvesting plants is another way to provide raw materials. Regardless of the agricultural fiber source, farmers focus on quality standards. Particularly, they ensure crops and animals have the best care because that leads to the highest quality fiber. Farmers’ efforts help makers and manufacturing sell a desirable good to customers. As a result, the farmer may earn a premium for the quality fibers, and they can still earn money for other quality, but not premium raw materials. Quality fiber helps the fibershed earn a favorable reputation.

Designers, Makers and Artisans

Makers, designers and artisans provide creative insight. Designers may process and make finished goods too. They design patterns for businesses and hobbyists to make clothing or crafts. Their keen eye for styles and trends creates appealing fiber goods for customers.

A designer’s textile knowledge helps farmers and manufacturers use raw fiber. For example, fine, soft, and coarse fibers are different. Each type has a purpose. For instance, soft sweaters and hats are desirable. However, coarse fiber is useful in rugs, slippers, or furniture fill. Matching the fiber types to make a finished product is a practical way to reduce fibershed waste.

Processing and Manufacturing

A lot of sophisticated skills come in handy for processing and manufacturing fiber. For instance, farmers measure raw fiber quality (or rely on skilled professionals). Sturdy, uniform fibers are ideal. Using a combination of techniques such as sorting, grading, and testing provides practical insight to everyone in the fibershed. For example, farmers may use it to plan how they will market the fiber. On the other hand, the data can help manufacturers and makers estimate how much, and what finished items to make, or which types of processing techniques to use.

Manufacturers turn raw materials into items customers use. This could be spun fiber, yarn, or large rolls of fabric. Another example of a useable good is a finished design or textile, such as clothing, rugs, and blankets. Additionally, manufacturing and processors may dye or color the fiber.

Colors and Dyes

Colors and dyes can enhance the fiber, creating eye-catching designs and patterns. Coloring and dying can be a small- or large-batch process. For example, smaller scale makers might create their own dyes and coloring. Fibershed purists aim to source dyes from within the fibershed. One way to do this is by foraging or farming plants.

Regardless of how or where the coloring and dyes are sourced, it is a chemical process. Proper safety, accurate measurements, and careful notes of each step are important—much like in a scientific laboratory. The attention to detail and care fosters responsible fibershed stewardship.

Shopping for a Maine fiber product

Customers support the fibershed economy. Retail shops and farms sell Maine-grown, designed, and made fiber goods. Shoppers will find clothing, blankets, throws, and rugs. Another way for shoppers to enjoy local fiber is to craft their own items. For example, makers can visit Maine shops or farms that sell undyed, and dyed yarn, roving, and other fiber materials. Some shops even feature patterns created by designers and artisans.

Farmland, Soil and Compost

In its purest sense, the fibershed is a complete cycle. The majority of the steps happen within the fibershed, including the disposal of waste, and the raw materials and dyes are not synthetic. Generally, recycling helps reduce waste. As fiber wears past its original use, it can be renewed into a different fiber good. However, if the fiber is not upcycled, or turned into a different good, composting is a useful alternative.